Furukawa Electric Innovation history

since 1884

The Furukawa Group's founder, Ichibei Furukawa, worked to build a new Japan with the aim of "making Japan brighter."

Having inherited Ichibei's idea, we have a great sense of mission to "make the world brighter."

Going forward, the Furukawa Electric Group will, as pledged in our corporate philosophy,

"contribute to the realization of a sustainable society" through continuous technological innovation.

- Foundation & Dawning of a New Era

- Helping to Establish Japan's Social Infrastructure

- Expanding Overseas

- Continue to support people and society with a variety of unique technologies

- Strengthen the development of new technologies and services to solve social issues

1884~ Foundation & Dawning of a New Era

The origins of our company can be traced back to 1884, when Ichibei Furukawa first smelted copper in Honjo, Tokyo and Yamada Cable Works began manufacturing electrical cables in Takashima-cho, Yokohama.

The Furukawa Group's founder, Ichibei Furukawa, was born in Kyoto in 1832 and, showing a natural flair for business, became an executive of the Ono-gumi, a wealthy merchant house at that time. In 1877, he took over the operation of the Ashio Copper Mine. After overcoming a number of crises, he developed it into Japan's largest copper mine.

Our corporate logo, the Yamaichi mark, was established that year to represent the idea of specializing exclusively in mining.

He later installed some of the latest Western technologies, such as Japan's first full-scale hydroelectric power plant in 1890, and expanded operations on his way to building the foundations of the Furukawa Group.

Started Japan's first electrodeposit copper trial operations

Opened Honjo Copper Smeltery and Yamada Cable Works

Ichibei Furukawa overcame various difficulties at the Ashio Copper Mine before achieving success, and in 1884 decided to set up a copper smeltery at Fukagawa, Honjo to improve the uneven quality of crude copper. Around the same time, inventor Yoshichi Yamada, who had developed a method of manufacturing rubber-covered wires, established a wire manufacturing plant at Takashima-cho, Yokohama.

This is the founding year of our company, which grew from these two business origins.

Started manufacturing electric copper wires

During this period, there were a series of plans for laying long distance communications cables due to the Meiji government's telephone expansion program, resulting in growing demand for not only electric lighting and power lines but also communications cables.

The company started to manufacture electric copper wire early on at its Honjo Copper Smeltery, setting up what was then a state-of-the-art copper wire manufacturing facility. Production at this copper wire plant grew smoothly due to its high quality, contributing greatly to the upgrade of Japan's social infrastructure at the dawn of the Meiji era.

1900~ Helping to Establish Japan's Social Infrastructure

Catering to demand for electricity and communications in the then undeveloped Japan, Furukawa Electric expanded production to include various rubber and cotton-covered wires, and in 1915 manufactured the nation's first submarine electric cable. The company continued to support the establishment of Japan's social infrastructure with its global quality technical capacity, such as by installing an antenna on Tokyo Tower, the country's largest radio tower at the time.

On the other hand, the company has diversified its business since early on, launching its R&D of lead-acid batteries in 1911 and establishing the Yokohama Rubber Company in 1917, Fuji Electric Manufacturing (now Fuji Electric) in 1923 and Furukawa Aluminium (now UACJ Corporation) in 1959.

Laid the world's first non-loaded carrier submarine cable in the Tsushima Strait

Manufactured Japan's first submarine electric cable

A major goal of the engineers at that time was to produce submarine cables, which require an extreme level of durability. The only companies that could manufacture submarine cables in those days were European electrical wire manufacturers, but import goods became scarce due to a series of wars and so domestic production became necessary.

Furukawa Electric succeeded, through trial and error, in producing Japan's first submarine communications cables, and laid eight nautical miles of it in the Bisan Strait. It went on to build up a strong track record both in Japan and abroad, including manufacturing and installing submarine communications cables to China.

Installed an antenna and feed line on Tokyo Tower

The construction of Tokyo Tower marked the start of the era of full-scale television broadcasting. For Japan, still undergoing post-war reconstruction, it was a time of successful development due to the rapid economic growth of the late 1950s and early 1960s.

The Tokyo Olympics in 1964 accelerated modernization, as people buzzed with news from the television and their lives became richer than ever before. Tokyo Tower's antenna still towers majestically over its surroundings today, a significant mark on the cityscape left by Furukawa Electric's broadcasting-related project.

Years later, our technologies were also utilized in the Tokyo Skytree antenna.

1960~ Expanding Overseas

From this period, Furukawa Electric launched its full-scale efforts to enter the global market with the hope of spreading its technical strength around the world. While building up a track record in the Middle East, Southeast Asia, and elsewhere, it established manufacturing plants from Southeast Asia all the way to Brazil, laying the foundations for today's globalization.

In 1987, it built a new research laboratory in Yokohama, which has created all sorts of world-leading technologies and products.

Established company in Brazil manufacturing and selling aluminum power cables

World's first successful practical application of optical fiber composite oil-filled cables

Developed a fully automatic high-precision six-high rolling mill

In those days, the covering material for the submarine telephone line and coaxial cable spanning the Pacific Ocean was mostly brass produced by Furukawa Electric. This brass required a high level of thickness accuracy and was, for the day, an incredibly long product. In order to ensure a supply system of this covering material, Furukawa Electric designed and made its own ultrahigh precision rolling mills, fulfilling its responsibilities without incident.

Later, in 1964, the company built a revolutionary new rolling machine called a fully automatic high-precision six-high rolling mill. In spite of its simple construction, it performed as well as a 20-high rolling mill, while also making fully automatic operation a reality. The superiority of this rolling machine was recognized in academic circles too, and it received the Japan Society of Mechanical Engineers prize in 1965.

This fully automatic high-precision six-high rolling mill is still in operation today, and its copper strip products are used for vital precision parts, such as in the inner workings of luxury watches.

Installed a communications network in Bangkok, Thailand

At the time, the top priority social infrastructure program in Thailand was telecommunications network expansion in the metropolitan region of Bangkok. In 1968, a plan was set out by Telephone Organization of Thailand operator to upgrade the telephone network in the metropolitan region of Bangkok. Furukawa Electric won the order for the project despite competition from leading companies around the world.

The project involved installing 21 telephone exchanges and 122,500 terminals throughout the city of Bangkok and was the largest project in the history of telecommunications cable exports. Furukawa Electric completed this major project in 27 months, as per schedule, proving that our technical strength was valid worldwide.

Due to this success, we also accumulated know-how in relation to overseas projects, which has since led to further development of our global business.

World's first successful field trial of optical fiber cable

This is a system of converting electrical signals into strong and weak light, which is then conveyed along thin glass fibers. Back in the pioneer days of optical fiber, Furukawa Electric carried out the world's first successful field trial of an optical fiber cable.

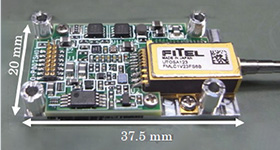

Since then, Furukawa Electric has supported high-speed large-capacity communications with its advanced technologies, having developed a series of technologies in addition to optical fiber cables, such as excitation lasers, vital for long distance communications, and ITLA for optical digital coherence, necessary for expanding communication capacity.

2000~ Continue to support people and society with a variety of unique technologies

We have continued to support people and society with a variety of unique technologies in response to environmental changes such as technological sophistication and climate change, based on our four core technologies of "metals", "polymers", "photonics" and "high frequency" which we have been strong in so far.

Developed a high-sensitivity immunochromatographic test kit using fluorescent silica nanoparticles

Successful development of carbon nanotubes with the highest electroconductivity in the world

Development of Persistent Current Technology Using Rare Earth Superconducting Wire Materials

Bought out the optical fiber division of Lucent Technologies in the US

OFS was the optical fiber solution division of the former Lucent Technologies in the US, itself originally evolved from Bell Laboratories. It has world-beating technologies and an abundance of patents related to different kinds of optical fibers, optical connectors, etc.

Furukawa Electric acquired OFS in 2001 to join the world's leading group of optical fiber corporations.

OFS is an important site in our optical fiber global strategy, and we have high hopes for its continued growth in the future.

Received the Golden Hadron Award from CERN for superconducting wire materials

This was the year when the superconductivity technologies developed over many years by Furukawa Electric truly blossomed.

Our superconducting materials were supplied to CERN (European Organization for Nuclear Research) for use in the very heart of its Large Hadron Collider (LHC). Furukawa Electric was permitted to start mass producing molded niobium-titanium twisted wire, which has the most uniform electrical and mechanical characteristics in the world, and in 2003 received the Golden Hadron Award from CERN.

Furukawa Electric's superconductor technologies have made a huge contribution to modern physics, such as CERN's research results later leading to the discovery of the Higgs boson.

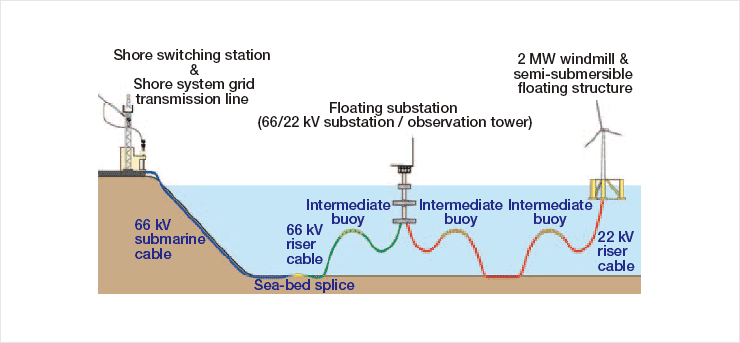

Participated in the Floating Offshore Wind Farm Demonstration Project

The Great East Japan Earthquake struck in 2011. The aftermath brought about fresh calls for stronger preparations against the threat of nature and a better response to the energy problem. Launched as part of the post-disaster reconstruction efforts, the Floating Offshore Wind Farm Demonstration Project in Fukushima is a colossal experimental research program to install multiple floating wind turbines in the sea and substations on land.

Furukawa Electric participated in this experiment in 2012, and was in charge of constructing the transmission system sending electrical power and control signals from the floating wind turbines to the shore. Floating wind turbines are constantly buffeted by waves and tides, and their submarine power cables also need to be able to withstand this harsh environment.

Furukawa Electric’s answer was to develop special high-voltage riser cables that float in the sea, and in 2013, for the first time in the world, we succeeded in connecting floating wind turbines to land substations.

Developed a high-sensitivity immunochromatographic test kit using fluorescent silica nanoparticles

Fluorescent silica nanoparticles successfully developed by Furukawa Electric consist of a fluorescent dye stably fixed inside nano-sized silica particles, and functional groups with connectivity with protein, etc. placed on the particles' surface. Their forte is their broad usage in the life sciences.

By applying this to fluorescent immunochromatographic technology for extracorporeal diagnosis, we have developed the world's first simple and quick test enabling the high-sensitivity detection of Acanthamoeba, a form of bacteria that contributes to eye infection.

In 2015, we also applied fluorescent silica nanoparticles in a new test agent for Campylobacter, a bacteria that causes food poisoning, greatly reducing testing times and increasing test sensitivity.

Successful development of carbon nanotubes with the highest electroconductivity in the world

Carbon nanotubes have excellent properties – one-fifth the weight of copper, 20 times the strength of steel, and 1,000 times the current density of copper. In 2015, Furukawa Electric, in collaboration with Shinshu University, succeeded in developing a carbon nanotube conductor with the highest electroconductivity in the world.

Going forward, Furukawa Electric will utilize carbon nanotubes' high strength, ultra-light weight, and environmental resistance to work on making electric wires lighter and lower-loss, thereby contributing to the realization of an energy-saving society.

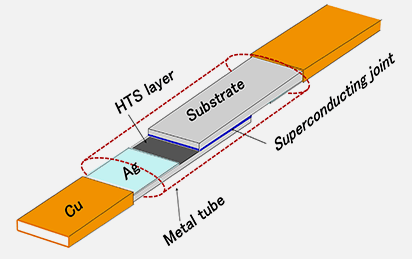

Development of Persistent Current Technology Using Rare Earth Superconducting Wire Materials

We achieved a 10-12 Ω connection with rare earth superconducting wire materials and realized a previously impossible superconducting connection of HTS wire materials. We have produced a persistent current maintaining a constant magnetic field for a long time (more than one year) with no external current supply. By obtaining a stable high magnetic field with low running power, producing a persistent current is expected the broader use of MRI in medical practice.

2016~ Strengthen the development of new technologies and services to solve social issues

"In order to build a sustainable world and make people’s life safe, peaceful and rewarding, we will create solutions for the new generation of global infrastructure combining information, energy and mobility.” under the "Furukawa Electric Group Vision 2030", we are working on research and development while strengthening co-creation with partners to solve social issues.

Successful development Narrow Linewidth & High Output Power Micro ITLA for beyond-100Gbps optical digital coherent transmission

Developed Thin Extra-high Count Multi-core Optical Fiber Cable with the World’s Highest Core Density

Award of contract for development of high voltage dynamic export submarine cable for floating offshore wind power plants

Practical application of "bipolar storage batteries", the likely winner in renewable energy utilization, offering a solution at 1/2 the total cost of lithium-ion batteries

Click here for research and development efforts