超小型コネクタ用銅合金条(EFCUBE®-ST)の開発に成功

スマートフォンやタブレット端末用に使われるコネクタの小型化が求められていた

古河電気工業は銅素材のプロフェッショナルとして、これまでに様々な用途に多くの銅合金条を開発してきた。近年、スマートフォンやタブレット端末などの小型化、低背化および多極化に伴い、搭載されるコネクタは、小型化が必須であった。

しかしながら、小型化を実現するためには、高いばね性と良好な曲げ加工性という、相反する特性を満たす必要があった。また、端子の短小化と断面積の減少に伴い、永久変形しにくい良好な弾力性(低ヤング率)及び高い電気導電性も求められていた。従来の代表的な高強度銅合金(チタン銅、ベリリウム銅)は、高導電性や低弾性の点で不十分であり、コスト面でも課題があった。

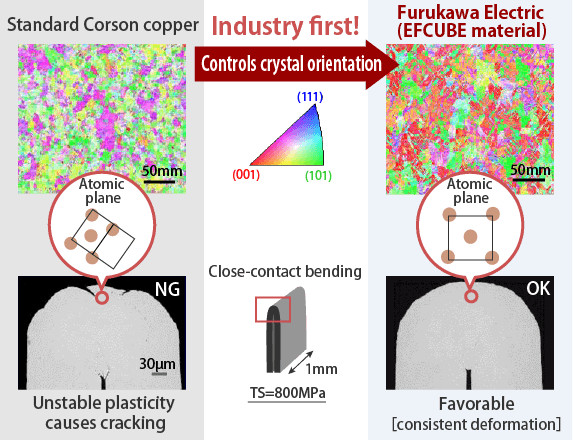

結晶方位を一定方向に揃える技術が課題を克服した

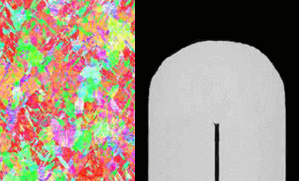

古河電気工業はニッケルとシリコンの濃度を高めた銅合金(コルソン合金)で高いばね性を維持しつつ、合金中の結晶方位を一定方向に揃える当社独自の技術を採用し、良好な曲げ加工性も実現した。また、ヤング率はりん青銅並みに低く、コネクタの接圧が安定して接続信頼性に高まる。導電率もりん青銅やチタン銅の約3倍で、耐熱性も高いため、バッテリーなどの大電流が負荷される電源系コネクタにも適している。

集合組織制御

本開発品の今後の展開について、当社日光伸銅工場長の島田は次のように語る。

「EFCUBE®-STニッケル・シリコンを高密度で析出させた合金であり、銅条・高機能材事業部(日光伸銅工場)に導入されている業界最高到達温度を誇る焼鈍設備を使用することで、組織制御技術を具現化した革新的な銅合金条を開発することができました。また、リードフレーム用途等で培われた生産技術力により、業界トップレベルの板厚精度、表面品質も実現しています。従来のEFCUBE®-820より高機能化ニーズの用途を狙って開発したものであり、今後さらに進化する薄型携帯電子機器の小型化に貢献していきます。」

開発品と他材料との特性比較

| 品種 | りん青銅(C5240) | チタン銅(C1990) | 開発品EFCUBE®-ST | |

|---|---|---|---|---|

| 特性 | ||||

| 電気特性 | 導電率 (%IACS) | × 10 | × 10 | ○ 35 |

| バネ性 | 0.2%耐力 (MPa) |

○ 800 | ○ 900 | ○ 900 |

| 耐永久変形 | ヤング率 (GPa) |

○ 110 | × 135 | ○ 110 |

| 曲げ加工性 | MBR(注) (幅1mm) | × 2t | ○ 1t | ○ 1t |

| 耐熱性 | 耐応力緩和性 | × | ○ | ○ |

| コスト | ◎ | × | ○ | |

(注) 最小曲げ半径: Minimum Bendable Radius。クラックを生じずに曲げ加工が可能な最小曲げ半径で、通常、板厚の倍数で表示します。小さいほど曲げ加工性が良好です。

シェア

シェア ツイート

ツイート シェア

シェア