屋外で長期間利用できる断熱材の開発に成功

紫外線による劣化を軽減できる、断熱材の開発が望まれていた

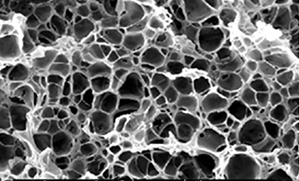

昭和30年代、古河電気工業はウレタンやスチレンの発泡体より熱に強く、劣化しにくいうえ、耐薬品性が高い、化学架橋発泡ポリエチレンシート「フォームエース」を開発した。ポリエチレン系樹脂に架橋処理を施し、高倍率で発泡させた独立気泡構造を有するこの製品は、優れた断熱性と結露防止効果が特徴。金属屋根などへの裏貼り用の断熱材やエアコン用パイプカバー、スポーツ用品や雑貨をはじめ、建築・土木、家電、自動車など幅広い用途で活用されてきた。

しかし、基本的に屋内で使用する製品であったことから、屋外の構築物などに「フォームエース」を使用した場合、紫外線や風雨による劣化の進行が早まる恐れがあった。たとえ太陽光が直接当たらない所でも、屋外では地表面や構造物などから紫外線が反射する。そのため、製品を愛用する顧客から、紫外線による劣化を軽減できる断熱材の開発が望まれていた。

こうした要望を受け、古河電気工業は問題を解消すべく改良を進めてきた。そして、新たに「きららエース」を開発。金属屋根用の高機能断熱材として、2015年4月より本格的に販売を開始した。

軽量アルミ箔で表面を覆い、耐紫外線性を4倍以上に強化

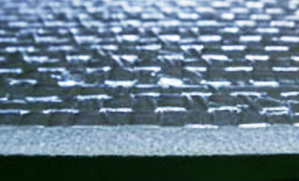

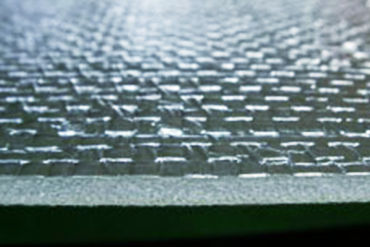

「きららエース」は、紫外線を反射する軽量アルミ箔で「フォームエース」の表面を覆うことで、紫外線による劣化を大幅に軽減。従来製品の4倍以上という耐紫外線性の実現に成功した。一般的な断熱材が720時間で表面に亀裂を発生させた促進耐候性試験(SWOM)において、「きららエース」は3000時間経過しても変化を見せなかった。これは約10年間、屋外で使用できる耐候性レベルだという。

また、高い光反射性による遮熱性能にも優れており、容器を用いた遮熱性試験では、従来製品に比べ夏場は内部の温度上昇を約10度、冬場は温度低下を約5度抑制できた。さらに、照明をより明るくする効果や防音性にも優れ、建屋内の快適性を高めることが可能だ。従来製品と同様に、金属板への貼り合わせや成型加工が簡単に実施できることに加え、従来製品に比べて長期間使用できることから、工場倉庫や駅舎、駐車・駐輪場などへの使用に適している。

高機能断熱材「きららエース」開発時に苦心したことや今後の展開について、古河電気工業の担当者は次のように語る。

「競合メーカーは耐候性フィルムを用いた製品をすでに発売している状況で、当社はより耐候性に優れたアルミ箔を用いた製品開発を進めてきました。顧客となる金属屋根の製造会社は、自社の設備で加工可能な製品を求めていたため、従来の断熱材と同じように加工できることが必要でした。しかし、アルミ箔は加工時に傷つきやすく、表面に損傷やシワが発生しやすい素材です。損傷はフォームの劣化の原因につながり、シワは製品の見栄えを損ないます。この問題の解決のため、全国のお客様が保有する設備で実機テストを繰り返し、ポリクロス加工をしたアルミ箔を選定することにしたのです。今後は、紫外線劣化の課題を抱えるカーポートや、屋外のひさし・廊下・階段などの金属屋根へのご採用を目指して、設計折り込み活動を進めていきます」

シェア

シェア ツイート

ツイート シェア

シェア