最先端医療デバイスを支える古河NT合金

ニッケル-チタン(Ni-Ti)合金(以下NT合金)は形状記憶特性と超弾性特性を併せ持つ合金として知られており、既にさまざまな応用製品が開発されている。特に最近は、医療分野において心筋梗塞や脳梗塞などの血管疾患系のカテーテル治療で、ステントやガイドワイヤ等医療デバイス用材料として使われている。大きな変形を加えても元の形に戻る特性やしなやかな特性(超弾性)を活かして、患者の体の負担を減らす低侵襲治療に大きく貢献している。

形状記憶合金と超弾性合金

金属は、外力(応力)による変形後、除力に伴い元の形状に戻ることができる変形量がそれぞれ決まっている。変形後に自力で元に戻る性質を「弾性」といい、その変形範囲を「弾性領域」、弾性領域の最大値を「弾性限界」という。弾性限界を超えた変形を加えると、金属自身では元の形に戻ることができず永久変形してしまう。低い温度で変形を加えたNT合金を一定以上の高い温度にすると元の形状に戻る。これを形状記憶合金という。一般の金属ばねと形状記憶合金のばねを組み合わせることで、特定の温度で動作するスイッチングを機械的に実現することができる。たとえば、温度の低いときは栓を閉めておき、温度が上がると栓を開いて熱や蒸気を逃がす機能などは形状記憶合金の得意分野である。

また、NT合金は室温で超弾性特性を発揮する。ステンレスやアルミなどの一般的な金属が永久変形するような大きな変形を加えても、超弾性合金は元の形状に復帰することができる。形状記憶特性と超弾性特性は、NiとTiの配合比率を変えることによりそれぞれの特性を変化させることができる。

形状記憶合金と超弾性合金の応力ひずみ曲線

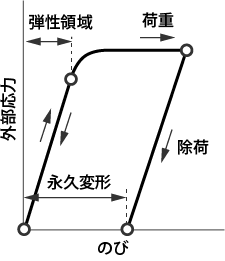

通常の金属材料

弾性領域を超えて力を加えると元の形に戻らない。

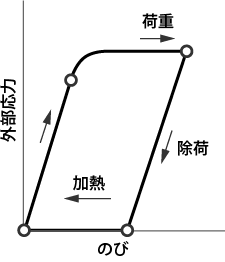

形状記憶合金

力を加えると変形するが、加熱すると元の形に戻る。

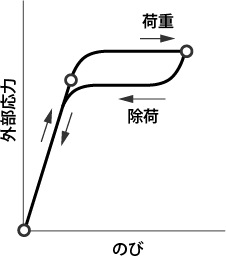

超弾性合金

変形後に力を除くとゴムのように元の形に戻る。

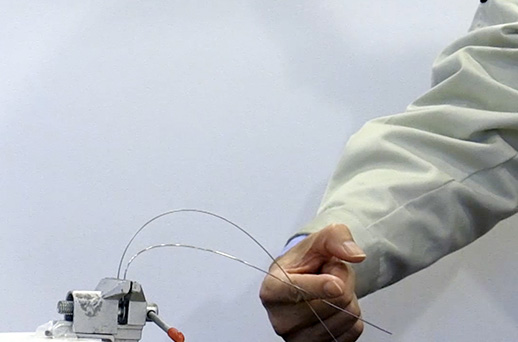

超弾性合金とステンレスの変形に対する挙動の違い

超弾性合金とステンレスを同じくらい変形させた状態

NT超弾性合金は力を除くと元の形に戻るが、ステンレスは曲がったままで元の形に戻らない。

関連リンク

超弾性合金の医療デバイス分野への応用

血管内で自己拡張するステント

血管は体内にはりめぐらされ、体のすみずみまで血液を運ぶ通路の役割を持っている。しかし血液の流路が狭くなったり、つまってしまうとその先の組織に酸素や栄養が行き渡らず、病気を引き起こす。時には血管が破裂して、深刻な症状を引き起こすこともある。そこでつまりの原因を取り除いたり、血管を広げて,血流を保持するといったカテーテル治療が行われる。

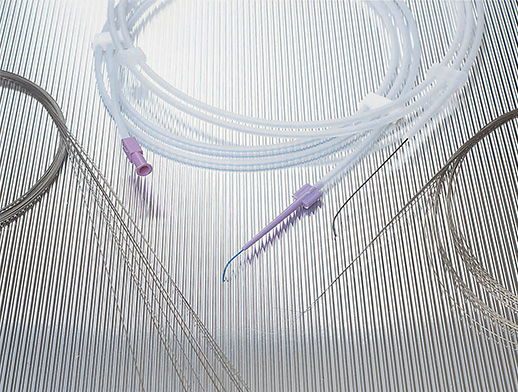

血管を広げる場合には、ガイドワイヤやバルーンと言ったデバイスが使われ、血管内腔を保持するために、網目状の筒のような形をしたステントと呼ばれる器具を血管に挿入する治療が行われている。超弾性特性を持つNT合金製のステントは細い筒の状態でカテーテルを通って患部まで届けられ、患部でカテーテルから放たれるとステントが所定の直径に自己拡張し、血管を内側から支える。超弾性合金製にすることで、内腔が大きく確保でき、人間の体の動きにもしなやかに追従することで、血管へのストレスを大幅に減らせるようになった。

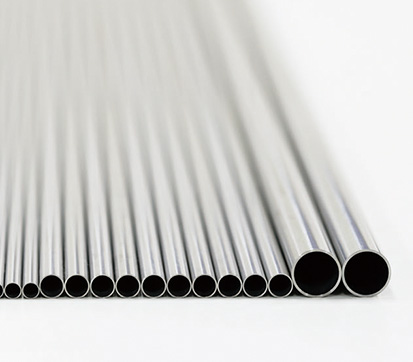

古河電工グループの古河テクノマテリアルはこの網目状のステントを製造するためのNT合金製のチューブを提供している。NT合金の難しさは配合比率が0.1%ずれるだけで、変態温度が約10℃変動し、機械的特性が変化することである。またNT合金チューブはステントに加工後、体内に留置されるものなので、ハイレベルな清浄度、真円度、生体内での安定性、高い耐久性が要求されるハイテク製品である。

ステントやカテーテルを患部まで送り届けるガイドワイヤ

ステントやカテーテルを、血管内の目的地まで送り届けるのがガイドワイヤだ。ガイドワイヤは血管の中をスムーズに進むためにしなやかな超弾性を持つNT合金ワイヤが使われており、さらに滑りのよい樹脂で被覆した構造となっている。

ガイドワイヤは人体の複雑に曲がりくねった血管内を奥へ奥へと通すために、血管の経路形状にそってしなやかに曲がりつつ、血管を突き破らずに、血管の挿入部で力を加えたときには血管の中を進んでいくある程度の硬さが必要だ。また、血管の挿入部でワイヤを回転させたときにはガイドワイヤの先端も回転する特性も要求される。ガイドワイヤには治療方法や適用患部によって多くのバリエーションがあり、それらの要求特性に応えるために、古河テクノマテリアルではさまざまな特性のNT合金製ワイヤを提供している。

株式会社古河テクノマテリアル 取締役 特殊金属事業部営業部長 堀川宏は次のように語る。

「当社の最大のメリットは、自社でNiTiのインゴットを製造する溶解鋳造から、熱間加工・冷間伸線、成型、記憶処理、さらに部品加工などの二次加工まで一貫した製造体制をとっており、それぞれのお客様に対し、きめ細やかな品質保証、スピーディーな開発・製造を行えることです。現在事業化を目指している「F-ELI(フルカワ・エクストラ・ロー・インクルージョン・ワイヤ;Furukawa Extra Low Inclusion wire)」は、合金内部にできる酸化物などの介在物を抑制することで高い耐久性を実現していることに加え、一貫製造体制により完璧なトレーサビリティが確保されていることも特長です。ステントやガイドワイヤを用いるカテーテルタイプの低侵襲治療は、患者への負担が小さく、医療費も抑えられるため、さらに多くの種類の治療方法開発が進められています。古河テクノマテリアルは、お客様からのご要望にお応えしてより高性能な製品の開発に取り組み、最終的には一人でも多くの患者さんの治療に貢献してまいります。」

シェア

シェア ツイート

ツイート シェア

シェア